Dr John Player, Director and Principal Engineer, presented this piece at the RaSiM 11 – Rockbursts and Seismicity in Mines conference at The University of Luleå in Sweden. The paper was authored collaboratively by Colin Thomson, John and Adama BARO.

Abstract

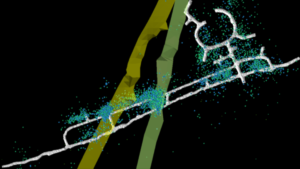

Due to an increasing seismic hazard at the Z55 underground mine at the Yaramoko project in Burkina Faso, a microseismic monitoring system was required to be installed. A system comprising seven sensors was designed to capture the remaining life of mine stoping areas with an event location accuracy of between 20-50m based on past experience. Several issues occurred during installation due to hole blockages resulting in late changes to the system design but with accuracy still in the desired range. Monitoring systems, hazard management plans and trigger action response plans were successfully implemented providing safer operational controls to withstand the risk posed by seismicity. System health has generally been good with occasional outages which are discussed to provide examples of operational experience for other sites considering microseismic systems.

Keywords: microseismic, seismicity, monitoring, hazard management

Introduction

Yaramoko mine site is an underground and open pit gold operation in Burkina Faso owned by Roxgold, a Canadian based gold operator. Mining of the Z55 underground mine at Yaramoko commenced in 2015 and has extended to a depth of approximately ~1100 mbs as of the start of calendar year 2025.

The onset of stress related damage and ground noise at a depth of approximately 750 m below surface at Z55 precipitated the need to purchase a microseismic monitoring system to quantify the associated seismic hazard at the mine. The system was designed by consulting engineers from MineGeoTech who provide geotechnical support to the mine.

In June 2024 the system was successfully commissioned by the Institute of Mine Seismology (IMS) which included two NetSPs, four 14 Hz triaxial geophones and three 14 Hz uniaxial geophones. Along with the seismic system installation, a set of Trigger Action Response Plans (TARPs) and procedures were developed to manage the seismic hazard on site.

This paper will present details of the mining environment, system design, system installation, an assessment of the seismic hazard, and the design and implementation of the site procedures and processes developed to manage the hazard.

Yaramoko Mine

The Yaramoko mine site is located 200 km southwest of the capital Ouagadougou in Burkina Faso. It includes two underground mines, Z55 and Bagassi South and one open pit at the Z109 deposit. The Z55 underground is the largest of the three and is accessed via a single access portal from the surface to the bottom of the mine approximately 1100 mbs.

The mining method at Z55 is longhole stoping with cemented rockfill (CRF) backfilling. Mining areas are divided into four level panels which are mined bottom up with the fourth level in each panel left open as a sill level with rib pillars between stopes.

Roxgold own and operate the Bagassi South deposit while Z55 and Z109 are contractor operated with African Underground Mining Services (AUMS) the primary contractor at Z55.

Geology

The Yaramoko project is situated at the northern end of the Hounde Greenstone belt which is 400 km long by 60 km wide. The Z55 orebody consists of a gold bearing quartz vein that is hosted within a shear that crosscuts a granitoid body with inclusions of altered volcanic rafts. The mineralized portions of the shear are expressed as a quartz vein in the brittle deformed granitoid body and appears to be ductile deformed with mineralized mafic volcanics. The shear is laterally extensive, up to 400 m along strike.

The granitoids and mafic volcanics form both the hangingwall and footwall of the shear zone and are competent lithologies prone to brittle failure with uniaxial compressive strength (UCS) values ranging from 100-180 MPa for the granite and 97-171 MPa for the mafic volcanics and Young’s Modulus values of approximately 30 GPa for both.

Mine layout

The Z55 deposit is accessed by a single decline from a surface elevation of approximately 5320 mRL (Figure 2). The portal was developed from a box cut with no open pit operations above the underground mine.

Each level is accessed via a central access drive off the main decline. The sublevel interval was previously 17 m but was updated to 20 m from the 4774 level down to reduce the amount of development required in the mine.

The decline design was a corkscrew design with partially overlapping decline stockpiles on every level. At the onset of rock noise and stress related ground movement, the decline was initially shifted to the west at the 4492 level to avoid some geologist modelled faults with stockpiles on alternating sides of the level access until changing to a figure-eight decline design from the 4410 level down due to the increasing seismic hazard and the small pillar between the stacked levels of the corkscrew design.

Stoping sequence was retreat back to the central access drive which was successfully employed for the majority of the mining at Z55 before needing to switch to a centre-out continuous retreat stoping front, requiring the introduction of footwall bypass drives from the 4470 level down.

Stress environment

Acoustic Emission (AE) testing was performed by the Western Australian School of Mines (WASM) in January 2025 to estimate the in-situ stress field at Z55 due to the seismic hazard at the mine. Samples were collected from a depth of 604 mbs and 953 mbs. The results suggested the major principal stress is oriented perpendicular to the main orebody with a σ1 to σ3 ratio of approximately 1.8-1.9 (Figure 3).

Minor rock noise and signs of movement of rock blocks due to stress were observed at a depth of approximately 750 mbs, corresponding with a major principal stress to UCS ratio of ~0.26.

However, this stress assessment was not available in the early days of the onset of seismicity to assist in understanding the appropriate mine design changes required to mitigate seismicity activity and the rock mass and ground support scheme data from seismic activity.

The MGT Way is engineering advice

grounded in rigorous data analysis, enabling robust design.

Contact Us >

Our Services >

Meet the Team >

Explore Our Projects >